If you've been following us for the past 2 years, you've got a decent idea that I drive my Ecoboost Mustang extremely hard. Our last blog post covered upgrading our OEM turbocharger to the Turbonetics NX2 turbocharger provided by Full-Race Motorsports and Turbonetics themselves. For every action there is an equal and opposite reaction.. when adding more power to any vehicle, it puts that much more stress on every component. This time it being my clutch. On MS109, my 2.3L is pumping out over 450 wheel torque, far above the SAE OEM rating that my OEM clutch could hold and I felt it on every clutch and clutch kick.

Knowing that I would launch, clutch kick, road race and drift my car constantly, we turned to no one better than Competition Clutch for an aggressive clutch kit that would be able to withstand the abusive of my driving style. Little did I know they were actively searching for a test vehicle to provide feedback on their prototype twin disc. Since I was a kid, I had always dreamed of having a twin or triple disc clutch. The sound and chatter from YouTube videos provided those car raising goosebumps. With much excitement we signed a deal and in a few weeks Competition Clutch came through with their fulfillment.

Before you consider purchasing this, I will have to warn you about the downside of owning this clutch. This is in no way to deter you from your purchase or decision but to warn you of what you are getting yourself into if you are first time car enthusiast. First off, the pedal will be extremely heavy, you will need nearly 100 pounds of leg pressure to push your clutch pedal to the floor. The engagement is violent, it will shake, it will chatter and it is loud. This is all completely normal. The clutch DOES NOT LAST LONG. Most people will see about 50,000 miles out of a set of disc plates which are replaceable, driven to the limit you will see about 30,000 miles of usage. You will need to replace the throw out bearing / internal slave every service and install. Why is it like that? Well when you install a clutch that is designed to hold over 1000 wheel torque, constant clutch kicks and numerous of launches, all comfort and luxury goes out the window. If all of this is okay with you then feel free to continue reading, as a bonus, this article does cover a normal clutch replacement / install.

BEGIN INSTALL

Do you have your jammin tunes on yet cause this job is going be decently time consuming and needs to been with MUCH caution. You WILL need a 2 or 4 post lift to complete this job. WE DO NOT RECOMMEND that you do this on the ground for YOUR SAFETY. The MT-82 is a fat pig, you WILL need a transmission jack for this job. Difficulty of this job? 6.5 out of 10. The hardest part will be actually removing the heavy exhaust and driveshaft. Below, I will list all the tools, chemicals, items and miscellaneous equipment you will absolutely need to complete this job.

- OEM Genuine Ford Parts Clutch Slave Cylinder

- Motul DOT 4 Brake Fluid or any DOT 4 Brake Fluid

- Full set of metric sockets

- 3/8 ratchet

- Extra long extensions

- 3/8 impact wrench and gun

- Screw Jack (if you do not have a friend)

- Transmission Jack (ABSOLUTELY NECESSARY)

- Brake cleaner

- Blue Loctite

- Set of strong arms

First and foremost just like the turbo install, the car needs to be cold. You will be removing the entire exhaust system so unless you want your skin as crispy as KFC, pull the car on to the lift, position your lift points which are located at the front and rear of the pinch welds. Lift the car up with the wheels just above the ground, pop the hood, disconnect your negative terminal and go watch a few episodes of "Worth It" if you're foodie like me. The car should be cooled down enough for us to finally start our surgery.

STEP 1

Remove your shift knob, boot and reverse lock out.

Before we go all the way up in the air, make sure to remove your shift knob, leather boot and reverse lockout collar. Failing to do so first will not allow the transmission to come out.

STEP 2

Remove your downpipe and exhaust.

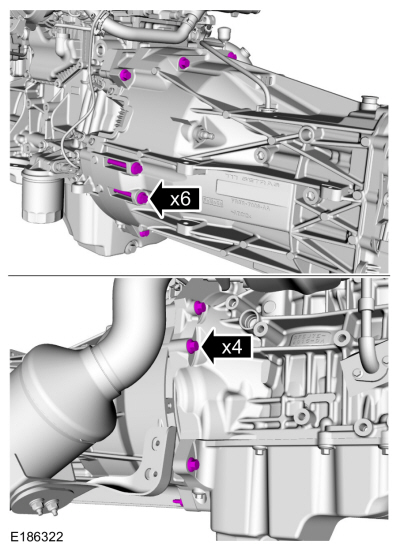

After you've completed removing those items, raise your Mustang all the way into the air and begin to remove the exhaust from the downpipe connection. You do not need to remove the downpipe from the turbine, only the bracket holding it to the transmission. Depending what exhaust you have, these steps will be different. As a generic reference, there are hangers on the center of the vehicle, rear differential and rear of the car. These are moderately easy to release. If you do not have a helping hand, make sure to take the exhaust off in sections so it does not come slamming down on the ground or worse, yourself.

STEP 3

Driveline Removal

After you safely remove the exhaust, start removing your driving line components starting with your entire driveshaft. Remove the bolts holding the carrier bearing, work your way to the back and remove the bolts holding the rear section of the shaft to the differential. DO NOT LET the driveshaft drop or you have just bought yourself a brand new one as they are worthless after being dropped. Pro tip, it's even labeled on the driveshaft itself.

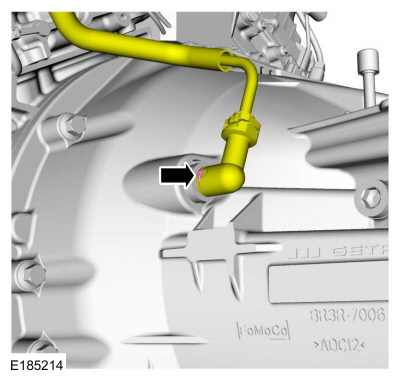

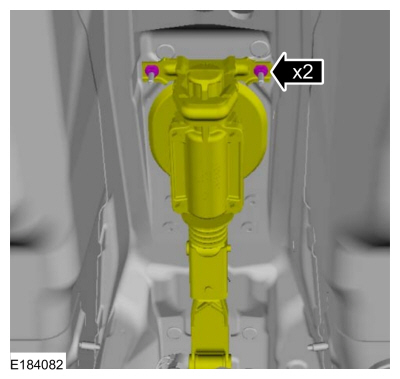

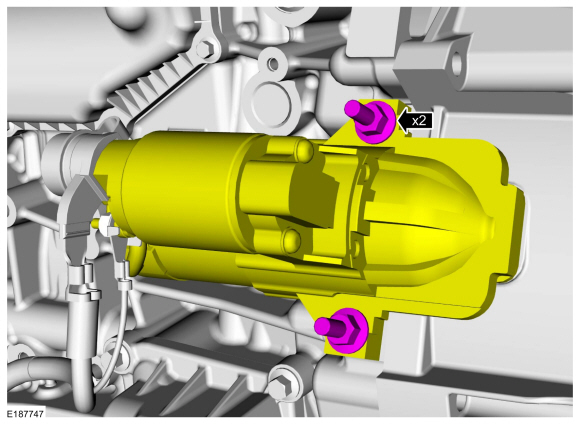

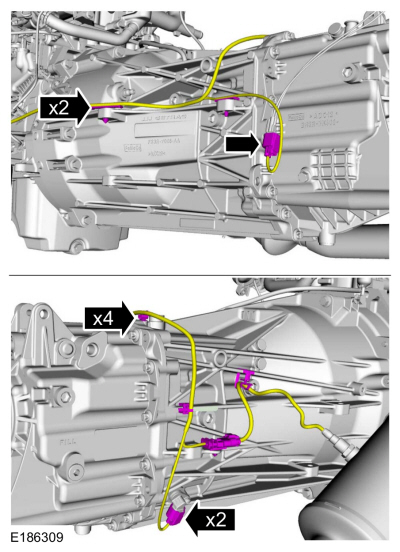

You've put the bolts back in the places they belong right? Don't lose anything or you'll be hating life on reassembly! Back to the front, disconnect the lead going to the starter and remove the starter unit. Grab a glove, rubber band and remove the clutch fluid line connected to the left side of the bellhousing, photo to the right for reference. Following the wire harness on the transmission, begin to unhook the the following sensors pictured to the right. Still at the front of the transmission, remove the following bolts that hold the transmission to the block pictured again to the right. Moving to the back of the transmission, support the transmission with a transmission jack and ratchet strap. Remove the 4 bolts holding the crossmember to the chassis. Remove the 2 bolts holding the linkage to the body pictured to the side. At this point, make sure that you have all of your wire harnesses disconnected, if you are 100% positive, let's begin to pry the transmission from the block. Use a medium pry bar and wedge it between the bottom of your bellhousing and block while your friend pulls back on the transmission itself. It should come out relatively easy. Carefully reposition your transmission and jack out of the way to begin removal of your OEM clutch.

STEP 4

Flywheel / clutch removal

This process is very straightforward, remove the six bolts holding the pressure plate to the flywheel. Discard these bolts as you will be using new hardware. Carefully remove your pressure plate and disc. Remove the 6 bolts holding the flywheel to the crankshaft. Discard these as well as new hardware is highly recommended. We are now ready for reassembly!

STEP 5

Reassembly

Begin by preparing all your parts. If you have purchased this exact clutch or some similar to it, these steps do also apply. Start by assembling these parts in the following order.

- Pressure plate

- Clutch disc (check markings for direction)

- Friction plate (check markings for direction)

- Clutch disc (check markings for direction)

- Clutch tool

- New slave / throw out bearing

Start by removing your old clutch slave cylinder and replace it with the new one, failing to due so could lead to premature failure. Next, assemble your pressure plate and discs. If you've done this successfully, it will look like the photo above. Failing to put the disc in the correct could lead to extreme chatter, disc failure or ultimately catastrophic failure of the unit under load. Be certain you have checked the disc markings on which way they face. Take your pretty new flywheel (if you purchased a twin disc or lightweight) and position it on the crankshaft and line it up the holes. With your new hardware, put a dab of blue loctite on the end and screw them in hand tight. You will need a friend to either hold the front of the crank pulley or use a pry bar in between the teeth of the flywheel to hold the engine from spinning, there is a factory service tool you can purchase to hold flywheel in place. Taken directly from the Ford Factory Service Manual, take your torque wrench and follow these steps to install your flywheel bolts in a star pattern.

- Stage 1: 37 lb.ft (50 Nm)

- Stage 2: 59 lb.ft (80 Nm)

- Stage 3: 83 lb.ft (112 Nm)

Now that your flywheel is installed, spray brake cleaner on the surface and wipe off any dirt or oil that was left on there from install. Grab your clutch assembly and mount it into place. It should sit flush with the mounting points. Shove the clutch tool in to make sure it touches the back of the pilot bushing ensuring everything is centered. Take your new hardware and dab them with blue loctite and install in the following order below. Factory torque spec is 26 lbs, it is highly recommended to use a digital torque wrench for the procedure.

Once everything is nice and tight, remove your clutch alignment tool and you are ready to reassemble. Repeat all steps backwards in the following order:

We recommend that you dab every bolt with blue loctite to ensure safety.

- Install transmission (this will be a little of pain to get the input shaft to center) DO NOT DRAW IT IN WITH BOLTS

- Install all bolts to the block

- Install 4 bolts crossmember to chassis

- Position your shift linkage to go back into the shifter hole

- Install 2 bolts shift linkage to chassis

- Install starter and leads

- Reconnect wire harness

- Reconnect clutch fluid line

- Install driveshaft

- Install downpipe

- Install exhaust

- Lower the car

- Reassemble your shift boot and knob

Now that your Mustang is on the ground AND YOU HAVE NO LEFT OVER HARDWARE we are almost to the fun part, driving it. Before we do that, we need to top off our clutch reservoir with recommend Motul DOT 4 brake fluid or any DOT 4 fluid. My personal favorite thing about this car is the self bleeding slave, start by pressing the pedal to the floor and picking it up with your foot until there is some pressure. From there, you will need to pump until you have SOLID pressure. This could take over 100 pumps to 10 minutes. Once you have established full pressure, go ahead and reconnect your battery terminals, set your clock and let's start the car.

1ST

IMPRESSIONS

The feel of a twin disc.

It will make noise, do not be alarmed. That is the clutch disc spinning between the friction plate, there is play between them and that is normal. It will make noise when you press and release the pedal, the pressure plate is designed to hold over 1000 lbs of torque. Press the clutch and release it VERY slowly as it will be extremely snappy. It will take you a few days to get used it and you'll want to give it about 100 miles of break in meaning, use it as much as you but do not rip on the car. We are trying to seat the clutch disc to the friction plates.

Quick Summary

- Time: 3 to 8 hours depending on skill level, we were to accomplish this job in 3 hours

- Cost: Clutch Packages can range from $500 to $1500

- You definitely need a friend on hand for this one

- A lift and transmission jack are absolute

- Don't forget to break it in

- Have fun with some burnouts and power slides after it's all said and done!

Looking to purchase this exact set up or any other Ecoboost parts of us? Shoot us an email below